EVOH High Barrier Shrink Film: Revolutionizing Food Packaging

Apr 22,2025The Power of Crosslinked Shrink Film: Revolutionizing Packaging Efficiency

Apr 14,2025The Unsung Hero of Packaging: Lidding Barrier Shrink Film

Apr 07,2025EVOH High Barrier Shrink Film: Revolutionizing Packaging with Protection and Sustainability

Apr 02,2025The Science Behind PCR Cross-Linked Shrink Film

Mar 26,2025The Composition and Properties of Polyolefin Shrink Film

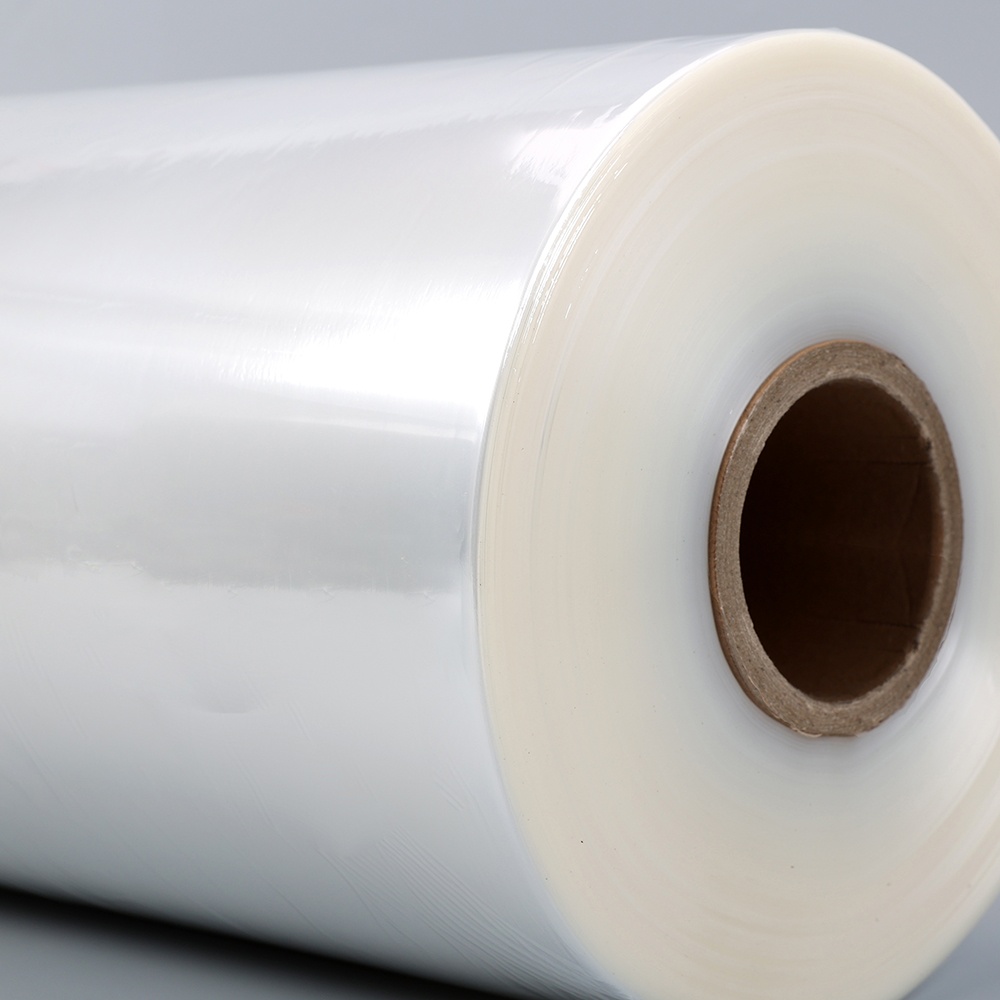

Polyolefin shrink film is composed of polyethylene and polypropylene, two types of polyolefin polymers known for their flexibility and clarity. This film is heat-shrinkable, meaning it tightens when exposed to heat, creating a seamless, snug fit around products. The film’s unique composition enables it to maintain its transparency and withstand rough handling, making it suitable for fragile or oddly shaped items.

Polyolefin shrink film is available in both cross-linked and non-cross-linked types. Cross-linked polyolefin provides greater strength and puncture resistance, making it ideal for heavier or sharp-edged items. Both types of polyolefin shrink film offer excellent shrinkage capabilities, covering products smoothly while maintaining high visibility.

Environmental Advantages of Polyolefin Shrink Film

Unlike traditional PVC shrink film, polyolefin shrink film is chlorine-free, which significantly reduces its environmental impact. When heated, PVC releases harmful chlorine gas, which is hazardous for operators and environmentally damaging. Polyolefin, by contrast, produces minimal emissions, making it safer for workers and the planet. Additionally, polyolefin is recyclable, which aligns with growing consumer and corporate demands for sustainable packaging solutions.

Advantages of Polyolefin Shrink Film Over Other Materials

Enhanced Transparency: Polyolefin’s high gloss and clarity enhance product presentation and allow consumers to view the item clearly through the packaging.

Strong Heat Resistance: This shrink film can withstand a range of temperatures, reducing the risk of warping or melting.

Reduced Sealing Temperature: Polyolefin shrinks at lower temperatures, which not only conserves energy but also minimizes the risk of damage to sensitive products.

High Elasticity: The film’s elasticity enables it to conform to products of various shapes, maintaining a secure hold even on irregular surfaces.

Practical Applications in Different Industries

Polyolefin shrink film is widely used in multiple industries due to its adaptability:

Food Packaging: Since polyolefin is FDA-approved, it’s commonly used in food packaging for baked goods, frozen foods, and produce, ensuring freshness and safety.

Pharmaceutical and Medical Products: The film’s transparency and puncture resistance make it suitable for packaging medical supplies, keeping items secure and visible.

Consumer Electronics: Polyolefin shrink film protects small electronics, gadgets, and accessories, providing tamper-evident seals.

Cross-linked shrink film has become a staple in the packaging industry due to its exceptional durability

Polyolefin shrink film has become a versatile packaging solution in various industries

Mobile site

alibaba

Copyright © 2023 Zhejiang Zhongcheng Packing Material Co., Ltd. All Rights Reserved. Privacy Polyolefin Shrink Film Manufacturers